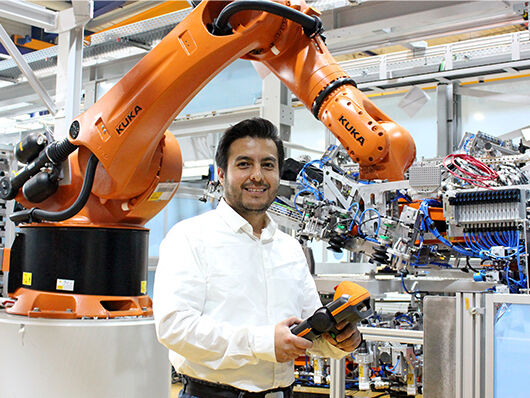

F.EEl the robot power – robot programming by F.EE experts

More than 40 years of experience in automation technology make F.EE a competent and reliable partner in the field of "robotics". In the field of robot programming – which is one of the core competences of the business unit "Electrical Engineering" – we cooperate with the market leaders in industrial robotics.

The F.EE experts have extensive know-how regarding the integration of robots from all well-known manufacturers (e.g. ABB, Dürr, Fanuc, KUKA, Stäubli, Universal Robots, Yaskawa) and the programming of various applications and requirements. We have always stood for uncompromising quality and on-time implementation in our projects in the field of programming industrial robots.

The F.EE service offer includes the following areas and activities:

Phase 1 – Concept

Feasibility analysis and layout creation.

Phase 2 – Construction und Simulation

Robot selection.

Reachability, payload and cycle time analysis.

Overall and safety layout.

Risk assessment.

Safety configuration.

Phase 3 – Offline-Programming

Creation of robot programs and application points according to standard specifications.

Collision check.

Interlocking concept.

Kinematics.

Creation of the SOP ( Simulation of Production ).

Documentation.

SOFTWARE:

Process Simulate.

Delmia V5 Robotics.

ABB RobotStudio.

FANUC ROBOGUIDE.

MotoSim Yaskawa.

Phase 4 – Virtual Commissioning

Creation and operation of a virtual robot system.

SOFTWARE:

fe.screen-sim.

KUKA.OfficeLite.

ABB RobotStudio.

FANUC ROBOGUIDE.

Phase 5 – Online-Programming

Robot and safety commissioning.

Optimization of robot programs and application points.

Process and quality optimization.

Automatic operation.

Cycle time optimization.c Documentation.

AREAS:

Handling.

Assembly.

Screwing.

Gluing.

Welding.

Soldering.

Camera systems.

Others.

Download

Find more information in our flyer „F.EEL THE ROBOT POWER" (Currently only available in German)!