Publications

Here you will find current publications on our fe.screen software products covering the topics of digitalization of industry and networked production: problem solutions, case studies, user descriptions and advantages and disadvantages.

fe.screen-analytics: Fundable energy management system

The German Federal Office of Economics and Export Control (BAFA) subsidizes the initial certification of an energy management system according to ISO 50001 and the associated investment costs.

Driving digitalization through plant simulation and virtual commissioning

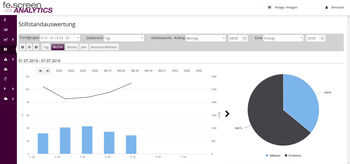

The condition monitoring solution fe.screen-analytics receives new functions for the analysis of production losses. This enables detailed downtime evaluations that make deviations in production more visible.

Don't be afraid of digitization. These are the five challenges in the Industry 4.0 era

The digitization of production offers manufacturing companies great potential for improvement. At the moment, many still shy away from actively driving their digitization process forward. Simply digitizing what already exists is not very effective. Instead, it is important to think about future challenges in advance of a project in order to derive the right steps for a successful project.

fe.screen-mes: The basis is crucial: How to make a successful MES selection

Challenges in implementing digitization projects in the manufacturing industry. There is a consensus among experts that, at least in many sectors such as the manufacturing industry, no company will be able to avoid digitization. Rather, they will be forced to face up to the issue in order to remain competitive.